The innovative pipe system in latest generation restraint joint polymer alloy complete with new wide radius bends. FITT Bluforce RJ: an effective response to the needs of integrated water system managers and an ideal solution for Horizontal Directional Drilling (H.D.D.)

Why choosing FITT Bluforce RJ?

The experience acquired in recent years with the production and promotion of the polymer alloy technology has confirmed the need to supply market players with a premium-quality product that is also capable of satisfying the highest technical-application standards in both the integrated water resources management market and the irrigation sector.

The overall expenditure for important projects such as water supply pipelines, sewage lifting stations and water infrastructures depends on the initial costs, but above all on the management and maintenance costs throughout the entire service life of the infrastructure, which should be as durable as possible and trouble-free.

To satisfy these needs, FITT – after developing the innovative FITT Bluforce technology and incorporating the inputs coming from the market (designers and managing bodies) – presents FITT Bluforce RJ: for the first time in Europe, a pipe made of thermoplastic material with an integrated and immovable mechanical sealing systeme.

FITT Bluforce RJ conforms to the IIP 1.1/19 technical specification, “Modified polyvinyl chloride (PVC-A) pipes for water conveying pipelines”, (Italian) Ministerial Decree no. 174 of 6 April 2004 (Water for human consumption) and the UNI EN 1622 standard, “Water analysis – determination of the threshold odour number (TON) and the threshold flavour number (TFN)”.

Reducing operating costs

FITT Bluforce RJ, – where “RJ” refers to “restraint joint” – can solve a series of necessities concerning both the design and laying phases, besides ensuring durable operation.

For designers it is far easier to design pipelines with restraint systems that do not require complex calculations to create thrust blocks; moreover, with the same type of pipe they can create sections that require mechanical seals and sections that do not require this technology.

Likewise, the company will have an easier task in laying the pipes, as they do not require external joints or, alternatively, concrete thrust blocks to be fitted in the restraint sections. Moreover, like for other polymers, long and delicate material welding operations are no longer necessary.

For the site management, it is an optimal solution for safely and rapidly completing network extensions and maintenance works on existing pipelines, resulting in shorter work times on-site without adversely affecting the durability of the polymer alloy technology.

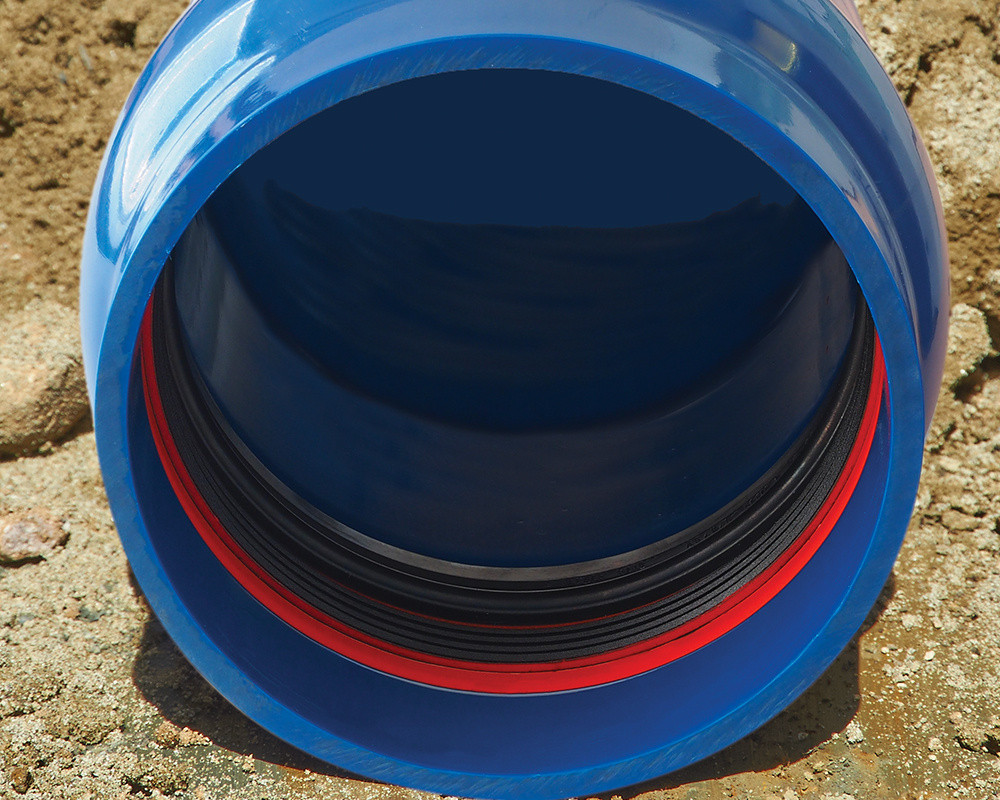

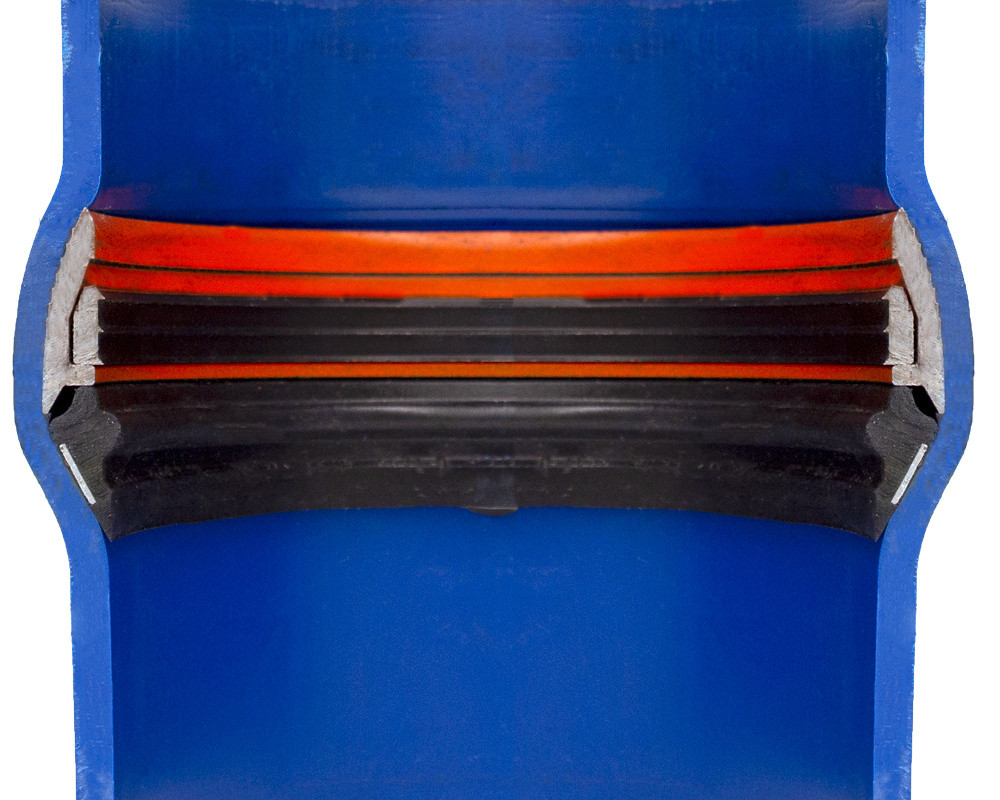

Bulldog® sealing system

FITT Bluforce RJ uses the socket-based jointing system with the seal mechanically hot-inserted in advance during the socket forming phase. The Bulldog® seal is made up of three elements that guarantee both the hydraulic and mechanical tightness of the joint:

- EPDM rubber sealing ring conforming to the EN 681 standard, certified according to Ministerial Decree no. 174/2004

- GJS 450-10 ductile iron envelope with epoxy protection applied through cataphoresis

- GJS 450-10 ductile iron mechanical sealing ring with epoxy protection applied through cataphoresis.

This hot pre-insertion method guarantees a totally stable seal, resulting in easy assembly, perfect functionality and optimal hydraulic and mechanical tightness of the pipes over time. The Bulldog® system is characterised by:

- rapid installation, thanks to the low assembly force

- high hydraulic tightness, certified by tests conducted in pressurised and depressurised conditions

- high mechanical tightness, guaranteed by the GJS 450-10 ring.

Thanks to this technology, it is possible to build pipelines without creating thrust blocks. Moreover, the pipes can be laid on terrains that are strongly sloping or prone to landslides.

The wide radius restraint joint bends

Complete restraint joint system

The Bulldog® gasket system of the wide radius bends allows the construction of pipes without the creation of thrust blocking blocks, as well as laying on soils characterized by steep slopes or landslides.

Avoid using anchor blocks

For the laying of pipelines in the presence of reduced dimensions, considerable slopes or poorly cohesive soils, the use of restraint socket joints makes it possible not to resort to concrete anchor blocks characterized by considerable bulk and performance influenced by the type of soil present.

Wide range of angles

Wide radius restraint joint bends are available to tackle 45° and 90° angles.

Pressure class

Pressure class PN 16

Horizontal Directional Drilling (HDD)

Horizontal Directional Drilling is a trenchless technology, suitable for installing new pipes without excavation. HDD greatly reduces disruption to traditional sites and, often, is the only solution for bypassing immovable obstacles in normal trench construction.

FITT Bluforce RJ is FITT’s thermoplastic pipe with built-in, integrated mechanical and hydraulic seal that meets the needs of designers, contractors, and water network managers.

The dual chamber seal, which is mechanically pre-inserted using heat, offers easy installation, perfect functionality and optimum hydraulic and mechanical sealing for the pipes. It also allows for installation on steep slopes or those subject to movement, making FITT Bluforce RJ ideal for trenchless operations such as Horizontal Directional Drilling (HDD).

Pipe assembly occurs during pullback phase and the impact on the site area is minimised. Handling is also much easier than with steel, cast iron – which are heavier and difficult to move – or polyethylene, materials that have been used in these types of application until now.

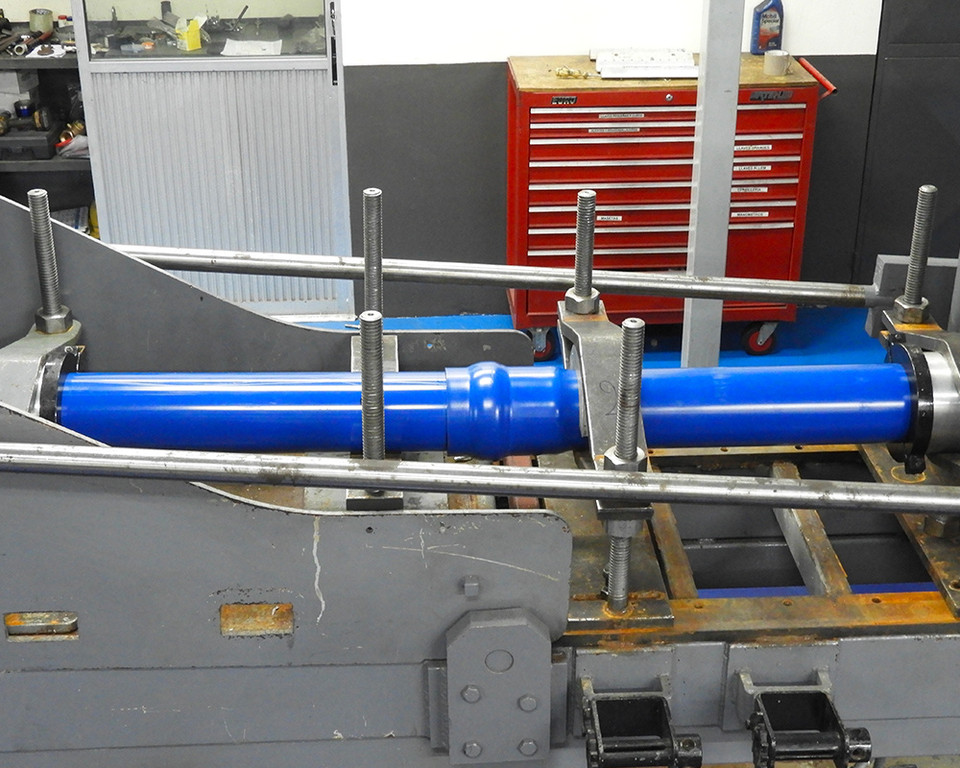

Tensile-resistant joint traction test

Reliability: FITT Bluforce RJ complies with regulations and certifications

FITT Bluforce RJ conforms to the IIP 1.1/19 Technical Specification, “Modified polyvinyl chloride (PVC-A) pipes for water conveying pipelines”, (Italian) Ministerial Decree no. 174 of 6 April 2004 (Water for human consumption) and the UNI EN 1622 standard, “Water analysis – determination of the threshold odour number (TON) and the threshold flavour number (TFN)”.

In 2020 FITT Bluforce RJ obtains the certification Kiwa Quality thanks to which, based on type tests as well as the periodic inspections conducted by Kiwa, is deemed compliant with the requirements of the Technical Document Ki-0410 Rev. 11, Annex K75 Rev. 02 and therefore marked KQ. Kiwa certification was issued in agreement to the Kiwa Cement Italia Regulations for Certification of product.

FITT Bluforce RJ is offered in the RAL 5010 blue version.

Bulldog™: performance and reliability over time

The benefits of the tensile-resistant joint

Designers

- Increased seal performance

- Timesaving on tests and inspections

- Hydraulic and mechanical seal guarantee

(positive and negative pressure) - Highest joint sealing reliability

- 2° angular deflection on joint (high offset)

- Chemical and electrochemical

corrosion resistance

Installers

- The pipe is supplied complete with an integrated seal

- Easy, fast and safe during assembly

- Reduced assembly force, even for large diameters

- Reduced labour for installation

- Manual assembly without machinery

- Save time and materials, anchor blocks are no longer needed

Plant Managers

- Guaranteed hydraulic tightness regardless of the joint’s deflection

- Pipe and gasket act as a single unit

- No risk of improper laying of the pipe

- System operation guaranteedf or both installer and plant managers

- Reduced operating costs throughout the life of the pipe