FITT Bluforce is the first PVC-A product range to achieve EPD® marking in Europe. This is the environmental product declaration that provides certified data on the life cycle of products, following the ISO 14025 and EN 15804:2012+A2:2019 international standards

The FITT Bluforce range provides utilities and freelance professionals with a wide range of solutions for infrastructural networks, now also completed with certified information on product environmental footprint.

FITT Bluforce and FITT Bluforce RJ meet the requirements for green procurement of Public Administrations (Green Public Procurement) and the Minimum Environmental Criteria for the road and building construction and maintenance sectors.

EPD®, what it is

The EPD® is a voluntary certification program that started in Sweden, and soon took on an international position as part of the EU environmental policy.

The EPD® follows the requirements of the UNI EN ISO 14025:2010 standard (Environmental declarations and labels – Type III environmental declarations) and is a tool for providing objective, comparable and reliable information on the environmental performance of products and services.

On one side, this declaration allows manufacturers to demonstrate their commitment to environmental issues, by analysing and describing their products in terms of their environmental impacts, while on the other side giving customers, designers and contractors the possibility of obtaining detailed information regarding the environmental characteristics of the product itself.

This means that the EPD® of the Bluforce range can provide relevant, checked and comparable information on the environmental impact of the PVC-A drinking water distribution network system conceived by FITT.

The advantages of the EPD® certification

Is international

the Bluforce and Bluforce RJ EPD® is a certified Environmental Product Declaration (EPD) that lists environmental data on the life cycle of Bluforce products, in accordance with international standard ISO 14025

Is reliable

the Bluforce and Bluforce RJ EPD® is based on the scientific principles of the Life Cycle Assessment (LCA), and is awarded following an independent assessment.

Is transparent

the Bluforce range environmental product declaration data are calculated and presented following the standard calculation rules contemplated for the product category of construction materials.

100% recyclable PVC-A

Once removed from the ground, the PVC-A pipes of the FITT Bluforce range are fully recyclable and can be mechanically turned into material for pipes with the same structural characteristics normally only obtained when using virgin materials.

Thanks to the long duration of PVC-A rigid products and the low waste flow volume, there are currently no limitations to the quantity of recycled PVC-A that may be used.

The recycling of FITT Bluforce PVC-A pipes is guaranteed because:

- the FITT PVC-A pipe does not contain plasticizers, and therefore is also phthalate free

- the FITT PVC-A pipe does not contain dioxins

- The FITT PVC-A pipe does not contain heavy metal additives, and therefore is lead and cadmium free.

FITT Bluforce and FITT Bluforce RJ are manufactured at our premises of Fara Vicentino (VI), powered by a trigeneration plant. Trigeneration is a process that allows the production of electricity and heat from the same energy source. Through absorption refrigerators, it also allows to use heat to obtain refrigerated water for conditioning and industrial process purposes.

The trigeneration plant can adjust the production of hot and cold water and electricity on the basis of manufacturing needs. It also makes it possible to eliminate any natural losses normally incurred during the transport of energy, therefore improving energy efficiency and reducing carbon dioxide emissions.

The sustainability of an environmental product declaration

Protecting the environment and biodiversity, reducing polluting emissions, using energy from renewable sources and acquiring low environmental impact habits are priorities that have now been included in the world political agenda and in common thinking. The EPD® sets the link between this need for sustainability and economic and industrial activities: for FITT, the monitoring of its environmental management policy means becoming familiar with it, developing and promoting it.

As an internationally recognised impartial tool, the EPD® allows us to make partners, operators and consumers aware of the environmental policies undertaken by the company, underlining the commitment and the sense of responsibility of FITT for the territory, the consumer and its stakeholders.

How is the environmental performance of the FITT Bluforce range calculated

The environmental performance of the Bluforce range indicated in the EPD® is based on the Life Cycle Assessment (LCA), in accordance with the ISO 14040 standard, the methodological foundation that ensures the objectivity of the information supplied, taking into account the specific calculation parameters for the product category (PCR) of construction materials following the UNI EN 15804:2012+A2:2019 European Standard.

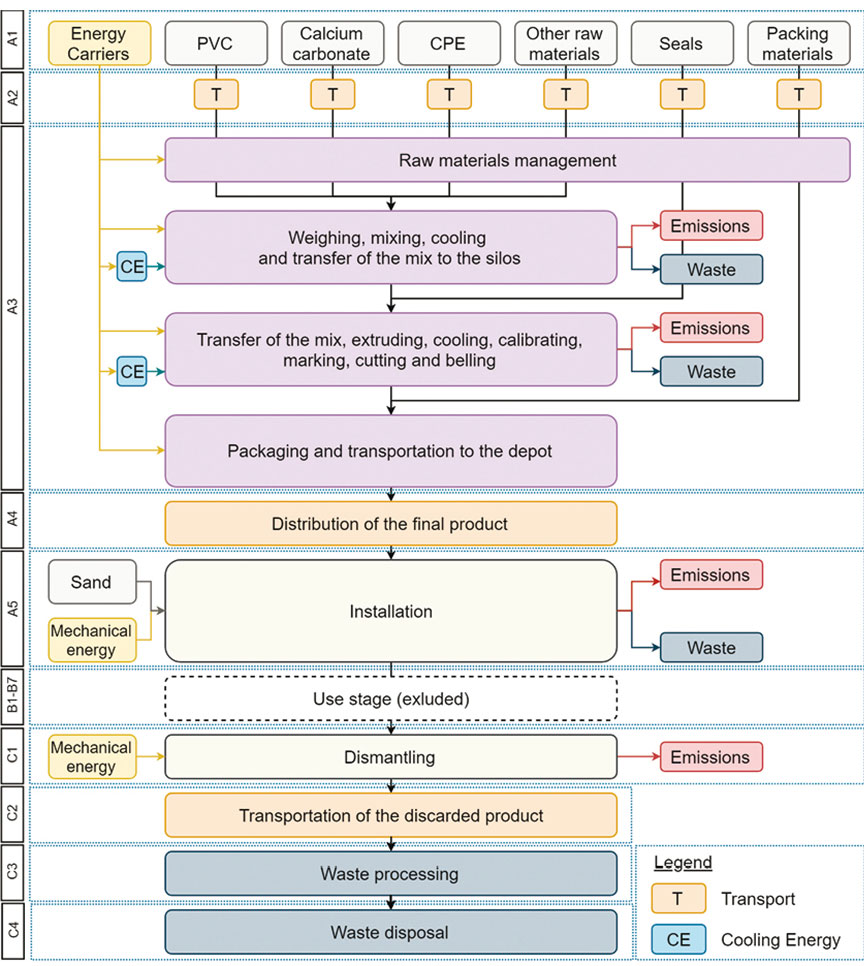

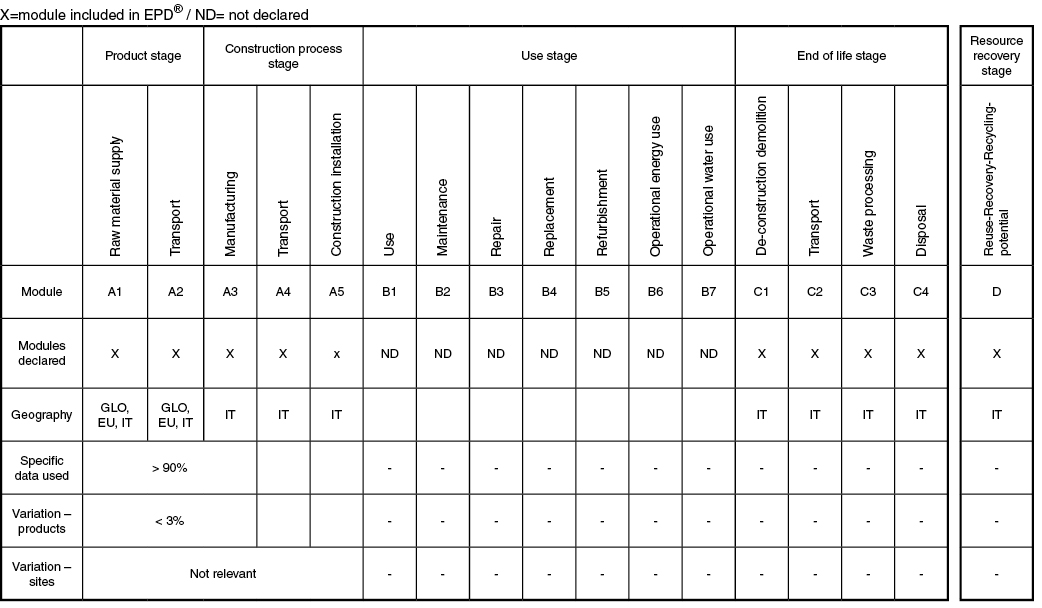

The new study adopts the “cradle to grave” approach and quantifies the impacts from the extraction of raw materials to the end of life of the finished product and its disposal. In the EPD, the results are split into the following stages:

A1: production of raw materials and energy carriers;

A2: transport of raw materials;

A3: manufacturing process at the FITT plant;

A4: transport of the pipe to the installation site;

A5: pipe installation;

C1: removal of the pipe from the installation site;

C2: transport of materials to the disposal and / or recovery center;

C3: waste treatment processes;

C4: waste disposal.

The environmental information obtained through the LCA was transferred in the environmental product declaration, which after having being assessed by SGS Italia, an independent credited body, is now available at Environdec.com, the portal of the International EPD System, the Program Operator selected by FITT that manages the processes for the writing of the Product Category rules, with a presence in over 45 countries all over the world (to date the environdec.com portal lists more than 1100 EPDs).

Environmental performance and use of resources

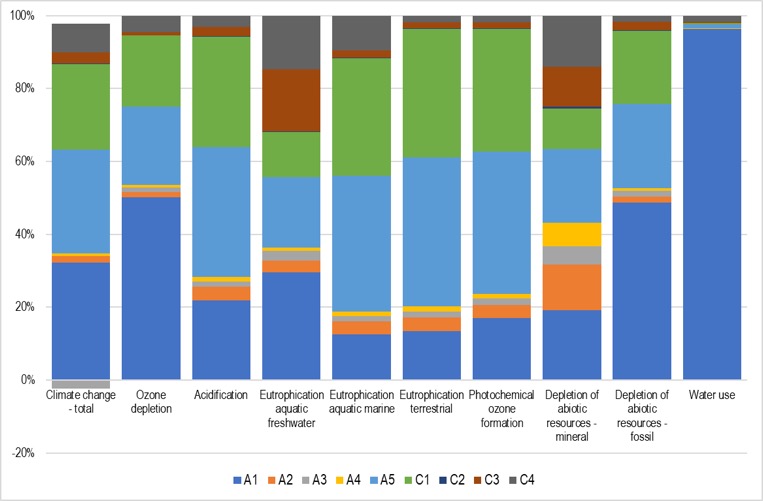

The Bluforce range EPD® contains an analysis of a set of impact categories, therefore offering a wide view of the potential environmental impacts, from climate changes to impacts associated with the use of water.

Abiotic Depletion Potential Elements: measures impacts associated with the consumption of minerals, metals, and similar materials;

Abiotic Depletion Potential Fossil Fuels: is a measure of the consumption of non-renewable energy sources;

Acidification Potential: deals with acidifying substances that have a wide range of impacts on soil, underground water, surface water, organisms, ecosystems and materials (buildings);

Ozone Depletion Potential: relates to the depletion of the stratospheric ozone, which can have harmful effects of human health, animal health, earth and water ecosystems, biochemical cycles and materials;

Global Warming Potential: climate change can have harmful effects on the health of ecosystems, human health and material wellbeing. Climate change is linked with the emission of greenhouse gases in the air;

Eutrophication Potential: includes all the impacts resulting from excessive levels of macro-nutrients in the air, caused by the emission of nutritional substances in the air, water and soil;

Formation Potential Of Tropospheric Ozone: photo-oxidant formation is the formation of reactive substances that are harmful for human health and ecosystems. This issue is also referred to as “summer smog”;

Water Scarcity: a measure of the consumption of the resource;

Utilisation of resources: the FITT Bluforce range EPD certifies that the use and the quantity of secondary materials and energy carriers used for the production of FITT Bluforce and FITT Bluforce RJ equals zero;

Particulate Matter emissions (disease incidence): measures the potential health effects due to the emission of particulate matter (PM 2.5);

Ionizing radiation, human health (kgBq U235 eq): represents the potential impact of ionizing radiation on the population, in relation to Uranium 235;

Ecotoxicity (freshwater) (Comparative Toxic Unit for ecosystems – CTUe): estimate of the possible effects on the species present in the ecosystem in a given time interval;

Human toxicity, cancer and non cancer (CTUh): the indicator measures the estimated increase in mortality on the population per unit of mass of chemical substance emitted;

Land use (Pt.): evaluates the impact related to land use.

A long certification path

The process for the obtaining of the environmental certification for Bluforce and Bluforce RJ started in 2019 and consisted of several stages. The starting point was the mapping of energy flows and the materials of the manufacturing plant of Fara Vicentino (VI), with the object of creating a dedicated database and of defining a quantitative approach for the measurement of such flows.

The second stage consisted in a timely identification of all the energies involved in each stage of the FITT Bluforce range manufacturing process, and the involvement of the whole supply chain for the mapping of the upstream flows.

The subsequent phases entailed the calculation of environmental impacts (carbon footprint) and the definition of the Lift Cycle Assessment (LCA) according to the requirements of the ISO 14040:2006 and 14044:2006 standards.

After certification by the independent body SGS Italia, following a “net audit” path, without non-conformities, the FITT Bluforce range environmental declaration is compliant to EN 15804:2012+A2:2019 standard and is now available on the Environdec portal, at the following address: https://www.environdec.com/library/epd1946

Environmental impacts related to the TOC installation of FITT Bluforce RJ

FITT recognizes the importance of incorporating environmental sustainability into corporate strategies. Environmental issues are now the subject of greater community awareness.

FITT has been attentive to these issues for some time, as demonstrated by our results aimed at minimizing waste, post-industrial recycling and after consumption, minimizing energy use in production as well as the energy incorporated in our products.

The characteristics of the special sealing system fitted to the FITT Bluforce RJ pipes allow them to be installed using the TOC (Controlled Horizontal Drilling) mode.

The TOC mode is a trenchless technology suitable for the installation of new pipes without having to carry out excavations in the open, able to significantly reduce the inconvenience of a traditional construction site and, at times, represents the only solution to circumvent unbeatable obstacles for normal trench excavation.

An evaluation of the environmental impacts associated with the pipe laying phase is therefore reported. This analysis was carried out on the basis of the primary data collected by the company relating to a site where 1200 meters of FITT Bluforce RJ DN 200 PN 20 pipes were laid. Data relating to the type and time of use of the machinery and information on the installation cadence.

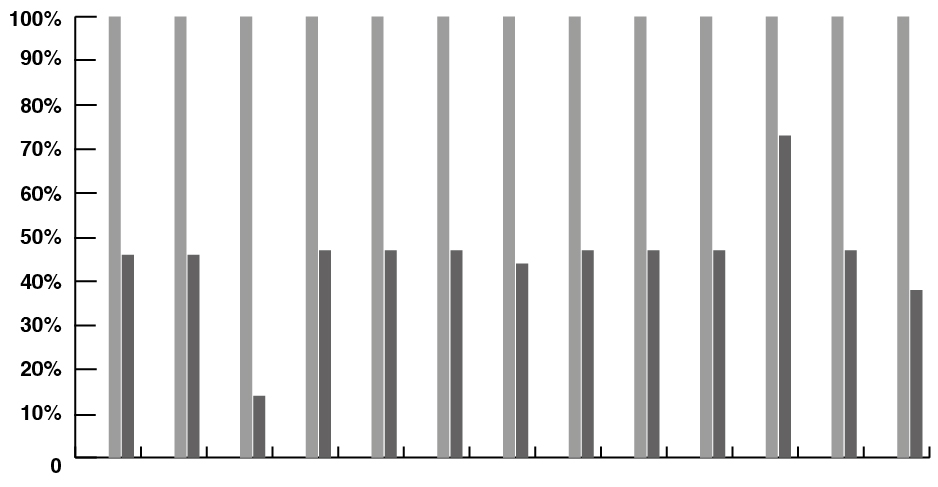

The following are the potential environmental impacts associated with the installation of 1 kg of FITT Bluforce RJ DN200 PN 20 based on traditional methods (basic scenario considered in this study) and in TOC mode.

The analysis of the contributions shows that for installation in TOC mode, over 90% of the impact in almost all categories is related to the use of machinery.

What the FITT Bluforce environmental product declaration contains

Program information: information relating to the registration of the product and the specifications regarding the calculation rules used for the construction material category, and the validity of the EPD®;

Product specific information: functional properties and the product content declaration;

Information regarding the environmental impact: Life Cycle Assessment (LCA), providing information on the use of resources and energy for the production of the FITT Bluforce range, and on the various types of emissions. All the values included in the study refer to 1 kg of piping system including seal. Conversion factors are also available, which allow to obtain details on the impacts of 1 metre of the specific DN/PN combination. The results are representative for all diameters and nominal pressures.

Additional environmental information: utilisation stage specific information;

Mandatory declarations: detailed information on the auditing procedure followed by the independent body SGS Italia.

Do you want to receive more information?

Fill in the form and you will receive the EPD® Bluforce directly in your email box!